Power generation

Applications

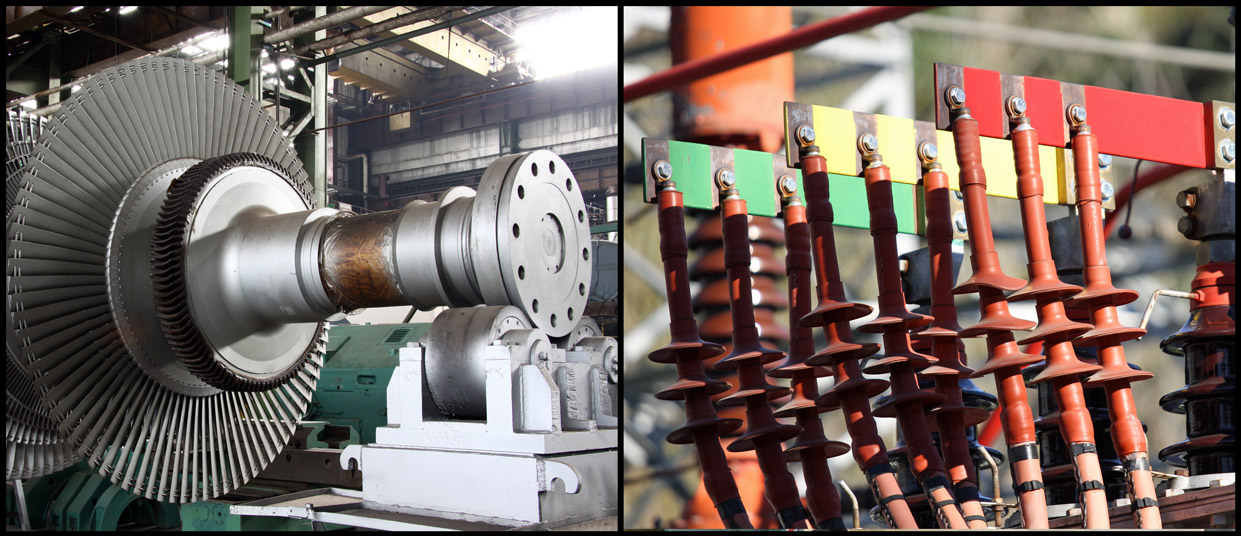

Components

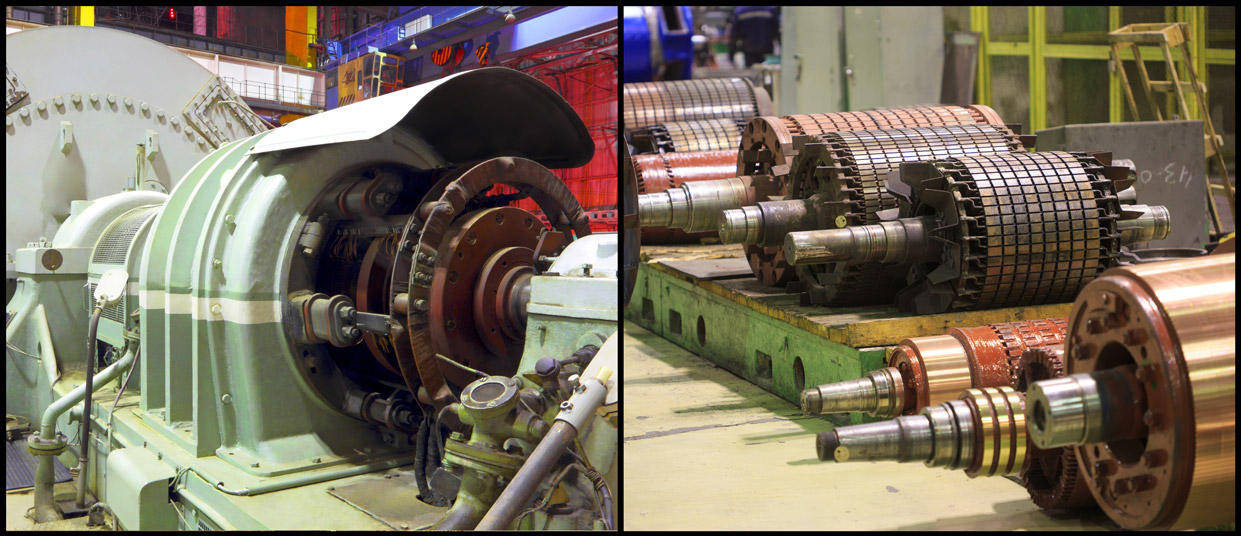

Motors & Generators

Electrochemical metallization is a method of choice for the repair of motors and generators.

The main areas concerned are the bearing surfaces (motor flange) and wheel bearing wedges on turbine shafts.

Applications

The motor flanges that house the bearings of the motor shaft often have contact corrosion in operation. Our portable process allows the selective electrolytic metallization of bores with copper, tin or nickel. In general, the machining of the bores before metallization is necessary only to restore the concentricity.

Selective electrochemical metallization of a worn bearing surface is faster and more efficient than dressing or thermal spraying processes.

DC motors and generator slip rings produce copper oxide films that reduce electrical conductivity and cause arcing and pitting especially during start-up of a stalled motor. Excessive deterioration is observed in highly corrosive environments, such as bleaching of pulp and paper mills. Deposition of a layer of 2.5μ (0.0001 in.) Of rhodium, then a layer of 1.3μ (0.00005 in.) Of gold on the switch, allows to space the frequencies of maintenance and prolong the service life.

Wind turbines

The first wind farms have reached a phase of their useful life requiring the rebuilding or replacement of drive shafts, bearing and gear systems for the repair of engines and generators. Kaytek CSP has realized the only reconstruction of the worn section of a wind turbine drive shaft in Canada; the metallization was carried out with a more durable metal than the original one. This operation, however, required the dismantling and transportation of this component to our facilities to be rebuilt.

On-site reconstruction or repair without dismantling

Kaytek CSP is currently developing the system that will enable direct machining and electrochemical metallization work with a portable combined system to be performed directly in the wind turbine tower.

This system will be operational in the fall of 2019.